Employers and consumers around the world are well aware of the ongoing labor and supply chain shortages impacting just about every industry–but few industries have been impacted as much as consumer manufacturers, as the global economy continues to recover from the pandemic. From expensive thanksgiving turkeys to delayed furniture deliveries, the impact of the supply chain crisis can be felt just about everywhere we look.

Due to U.S. and Canadian unemployment laws and benefits, many qualified workers are choosing to stay at home, causing a well-known labor crisis within the CPG industry. With increased consumer demand, supply chain disruptions along almost every touchpoint, and a lack of workers willing to take on jobs, some major grocers are receiving just 40 percent of what they ordered.

It’s becoming abundantly clear that many shelves will be empty well into 2022, and many field teams and retail stores will continue to be short-staffed. So what can brands and merchandising teams do to help guide their field teams through the ongoing labor and supply chain shortages right now? While many are skeptical of the Biden Administration’s plan to solve the supply chain issues soon – we have a few recommendations brands and merchandisers can make in order to make the most out of a trying situation.

Caveat - most of these recommendations come with an assumption that your team is using some kind of retail technology to enable them to be as efficient and effective as possible out in the field, in order to make the most out of their available resources.

The truth is, a strong retail execution platform can’t solve for SKUs being out-of-stock if there is no product available. In today’s economy, there’s much out of the control for your field team. But here are things you may be able to control: 1) Control over your field team, where they go, and 2) the actions they take every day in the store. So let’s dive into these new ideas.

Idea #1 - Identify and Correct On-Shelf-Availability Issues Faster Than You are Today

When supply is low in every store, it’s important that all available products find their way to the shelves. Your team will need a tool that can guide you to correct on-shelf availability opportunities even before they become issues.

Did you know that more than 30 percent of products are not on the shelves according to plan? And while each store presents its own unique challenges, the most common pains are typically one of these three; 1) Phantom inventory, which prevents reordering and leads to empty shelves; 2) When fast-selling products go out of stock, competitors often take your shelf space; 3) On-shelf-availability issues are only caught when reps are sent to the store, which leads to sales losses for your best-selling products.

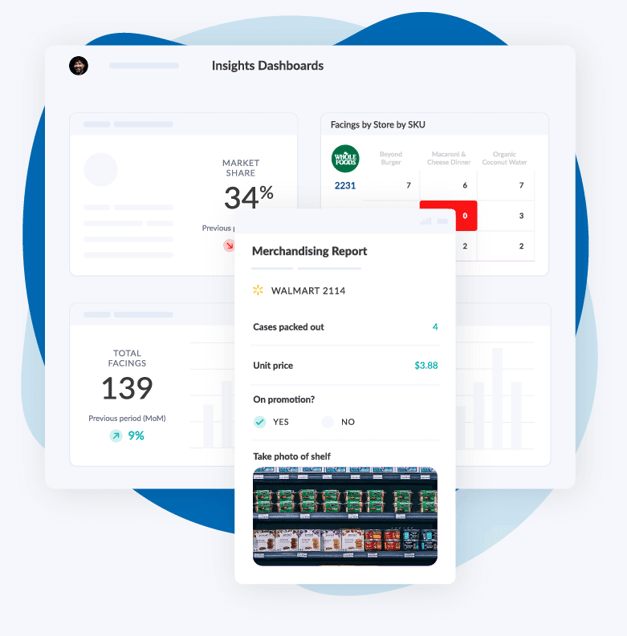

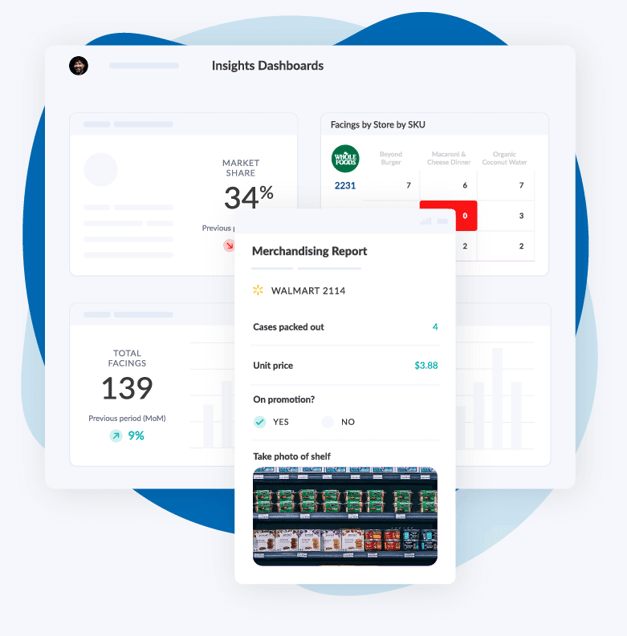

With a modern retail execution platform, field teams get a complete view of sales and execution in every store so they can focus on merchandising in the key accounts that drive the largest impact on sales, and here’s how:

On-Shelf Availability Reports: Team leads can use POS data from retail partners to automatically detect potential OOS and voids in-between store visits. They can review a dashboard of sales and highlight product sales where sales are at or close to $0 (then send the field team to follow up with the store).

Field Team Deployment: Once we’ve pinpointed on-shelf issues, assign follow-ups at the target stores so reps can get products back on the shelf.

Inventory Reporting: Once in the store, reps can compare reference on-hand inventory and compare it to inventory in the backroom correcting phantom inventory where appropriate.

Mobile Ordering: If inventory levels are low, reps can create replenishment orders right from the store.

With a retail execution platform that can empower your field team to identify and correct on-shelf availability issues faster, you can:

- Automatically detect empty shelves in-between store visits,

- Reduce the duration and cost of out of stocks

- And improve availability for your best-selling products.

Idea #2 - Monitor Program Compliance at Scale

When reps are tasked with covering a wide net of stores in a particular territory, it can be difficult to get a sense of how compliance is executed across the board. While you might know what’s happening in one or two stores, without having good data to cross-check against strategic goals, it’s typically hard to tell when your goals are met.

With the right tools, CPG field teams can instantly review planogram and display execution in all of your accounts, and here’s how:

In-Store Execution & Reporting: Complete surveys, share photos, and place replenishment orders, and immediately share results from the field. During stores visits, reps can complete surveys and share photos from the shelf, giving the team immediate insight into merchandising execution.

Planogram Audit Dashboards: At scale, field teams get summary levels dashboards of planogram compliance and merchandising execution across all key accounts, territories, and programs. This data can reveal trends in product availability, display execution, and competitive activity.

With a retail execution platform that can help your team monitor planogram compliance at scale, your team will be able to:

- Instantly review planogram and display execution in all of your accounts.

- Reveal trends in product availability, display execution, and competitive activity.

- Close shelf-level execution gaps faster.

Idea #3 - Make Smarter Decisions with Integrated Data from Major Retailers

Any modern retail execution platform should fully integrate with major retailers’ point-of-sale data feeds like Walmart, Target, Kroger, so that brands have a more complete picture of how products are sold at the store level.

Traditionally, it was shopper marketing and category management teams that cared the most about point-of-sale data. But more and more, field sales and merchandising teams are starting to leverage this data source as a way to estimate in-store conditions in-between store visits, as a way to guide their field plans. While previously they may have had to rely on pre-set routes and past store performance, real-time consumption data can help them remain nimble, prioritizing stores with potential retail execution errors, or opportunities for growth, and taking action sooner.

Below are four ways brands are using their syndicated point-of-sale data to find sales opportunities and optimize their retail activities in the field:

- Use store-level sales trends to find execution errors.

- Track SKU-level sales to anticipate out-of-stocks.

- Automate distribution voids.

- Equip reps with up-to-date sales data.

This gives your team a complete 360-degree view of sales and execution in your key accounts, highlighting all the data they can make available at store level: product placement, promotion compliance (materials), product availability, stock levels, and sales performance. In today’s unpredictable supply chain landscape, it’s critical your field sales team is equipped with the tools to take advantage of every opportunity on the shelf.